Computer Recycling: From Circuit Boards to Gold Recovery

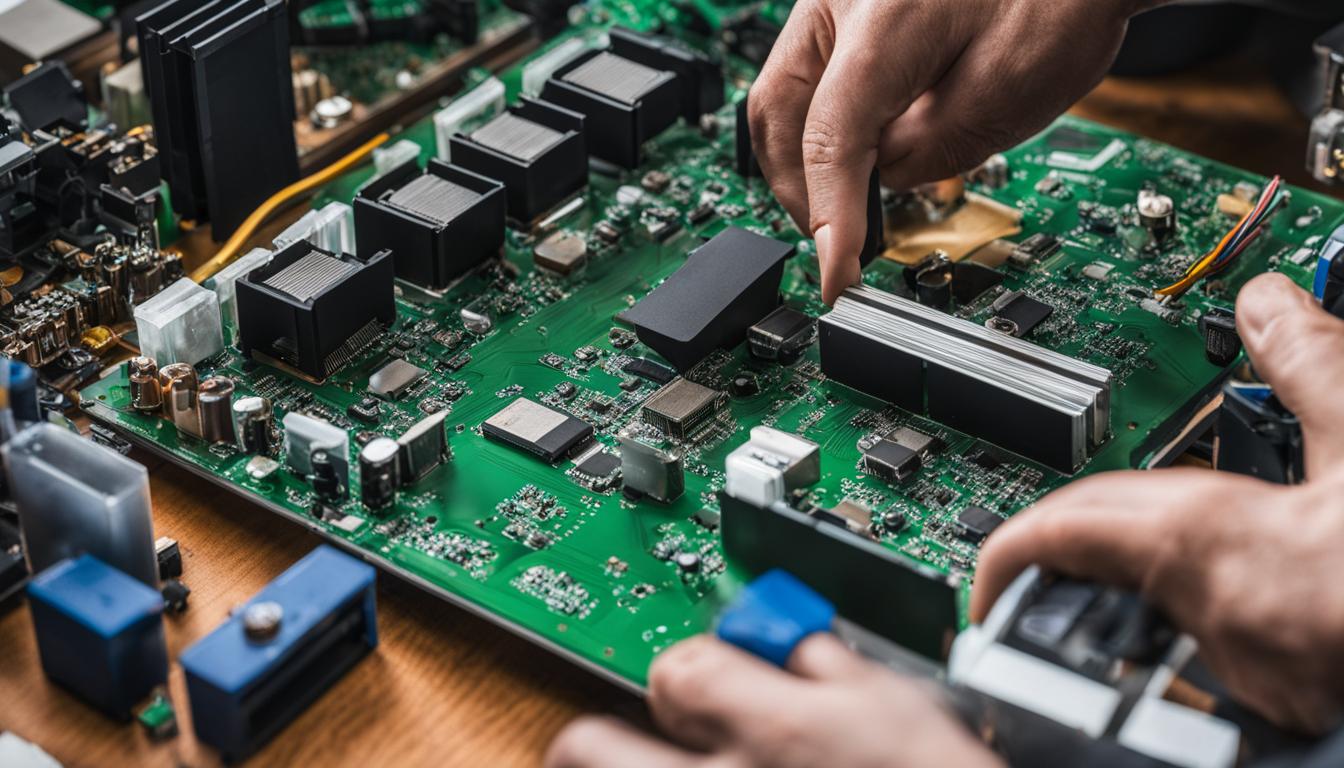

In today’s technology-driven society, the use of electronic devices is rapidly increasing, leading to a higher demand for mineral and metal resources. However, there is also a forecasted decline in mining extraction in the coming years. To address this issue and conserve resources, electronic components, especially circuit boards, are being recycled to recover precious metals like gold. This process is known as “urban mining” and involves methods such as manual gold removal, reverse electrolysis, and chemical solvent baths.

Key Takeaways:

- Computer recycling plays a crucial role in conserving resources and recovering precious metals.

- Circuit boards are a valuable source of gold and can be recycled through methods like manual gold removal and chemical solvent baths.

- Urban mining is the process of extracting precious metals from electronic waste, contributing to sustainability.

- Gold recovery from computers through circuit board recycling is financially rewarding and environmentally beneficial.

- Proper safety measures should be taken while handling chemicals and disposing of waste.

Methods for Gold Recovery from Circuit Boards

In the process of urban mining, various methods are employed to extract gold from circuit boards. These methods offer effective ways to remove gold and recover precious metals from electronic waste. Here are some of the commonly used techniques:

1. Manual Removal

Manual removal involves physically separating the gold from the circuit boards. This method requires patience and precision as the gold needs to be carefully separated from the other components. Although it can be time-consuming, manual removal yields good results and is suitable for individuals with the right tools and expertise.

2. Reverse Electrolysis

Reverse electrolysis is another method used to extract gold from circuit boards. In this process, a chemical solution is used along with electricity to remove the gold. The circuit boards are submerged in the solution, and the application of electrical current causes the gold to separate from the boards and collect at the electrode. This method is effective and relatively simple to perform.

3. Chemical Solvent Baths

Chemical solvent baths involve the use of powerful chemical solutions to dissolve the gold from the circuit boards. The boards are immersed in the solution, and the gold is extracted through a series of filtration and purification steps. This method is efficient and can yield a high amount of gold recovery. However, it requires caution and proper disposal of the chemical waste.

Table: Comparison of Gold Recovery Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Manual Removal | Highly precise results | Time-consuming |

| Reverse Electrolysis | Relatively simple process | Requires electrical equipment |

| Chemical Solvent Baths | High gold recovery rate | Requires proper chemical waste management |

Each method has its own advantages and disadvantages, and the choice of method depends on the individual’s skill level, available resources, and the desired level of gold recovery. It is important to note that these methods should be carried out with proper safety precautions and in compliance with environmental regulations.

Tools and Chemicals Needed for Gold Recovery

When it comes to extracting gold from circuit boards, there are certain tools and chemicals that are essential for the process. These tools, along with protective equipment, ensure the safe and efficient recovery of gold from electronic waste.

Gold Recovery Tools

The following tools are commonly used in the gold recovery process:

- A glass container: Used to hold the circuit boards during the extraction process.

- A metal bowl or tray: Useful for breaking down the circuit boards into smaller pieces.

- A glass or metal rod for stirring: Helps in mixing the circuit boards with the chemicals for gold extraction.

- A cloth filter: Used to remove impurities and separate the gold from the chemical solution.

- Steel tweezers: Ideal for manually separating the gold from the plastic components of the circuit board.

These tools are readily available and can be easily acquired for the gold recovery process.

Chemicals for Gold Recovery

Various chemicals are needed to extract gold from circuit boards. The specific chemicals used may vary depending on the chosen method of gold recovery. Some commonly used chemicals include:

- Concentrated nitric acid: Used to dissolve the metallic components of the circuit boards.

- Hydrochloric acid: Helps in breaking down the circuit board material.

- Hydrogen peroxide: An oxidizing agent that aids in the gold extraction process.

- Methanol: Used for washing and purifying the extracted gold.

- Gasoline: Employed in the fire method of gold extraction.

It is important to handle these chemicals with caution and follow proper safety protocols throughout the gold recovery process.

| Gold Recovery Tools | Chemicals for Gold Recovery |

|---|---|

| A glass container | Concentrated nitric acid |

| A metal bowl or tray | Hydrochloric acid |

| A glass or metal rod for stirring | Hydrogen peroxide |

| A cloth filter | Methanol |

| Steel tweezers | Gasoline |

By using the appropriate tools and chemicals, individuals and companies can effectively recover gold from circuit boards and contribute to the recycling of electronic waste. However, it is crucial to handle these materials responsibly, taking necessary precautions to ensure personal safety and environmental conservation.

Step-by-Step Guide for Extracting Gold from Circuit Boards

Extracting gold from circuit boards can be a meticulous process that requires careful attention to detail. There are several methods that can be used, each with its own steps and considerations. In this step-by-step guide, we will outline three popular methods for extracting gold from circuit boards: using nitric acid, using hydrochloric acid and hydrogen peroxide, and using fire.

1. Using Nitric Acid

To begin, break the circuit board into small pieces and place them in a glass container. Next, pour nitric acid into the container, ensuring that all the circuit board pieces are covered. Allow the mixture to sit for some time, typically a few hours or overnight, to allow the nitric acid to dissolve the gold. Once the gold separates from the plates, strain out the nitric acid. You can do this by pouring the mixture through a cloth filter or using other appropriate filtration methods. Finally, manually separate the remaining pieces containing gold from the plastic components.

2. Using Hydrochloric Acid and Hydrogen Peroxide

Similarly, break the circuit board into small pieces and place them in a glass container. In this method, create a mixture of hydrochloric acid and hydrogen peroxide and pour it over the circuit boards. Make sure that all the pieces are submerged in the solution. Stir the mixture daily for about a week, allowing the acid to break down the circuit board and dissolve the gold. Over time, you will notice the acid darkening and the gold flakes separating and floating on the surface. Once this occurs, filter the mixture to separate the gold flakes. Rinse the flakes with methanol and water to remove any residual chemicals.

3. Using Fire

The fire method involves breaking the circuit board into small pieces and placing them in a metal container. Sprinkle gasoline on the plates and carefully set them on fire. Regularly turn the pieces to ensure even exposure to the flames. Once the circuit board pieces are charred, allow them to cool down before manually separating the gold from the plastic components. It is important to exercise caution and follow appropriate safety measures when using fire as a method of gold extraction.

By following these step-by-step guides, you can extract gold from circuit boards and contribute to the recycling of electronic waste. Each method has its own advantages and considerations, so it is important to choose the one that best suits your resources and capabilities. Remember to take proper safety precautions when handling chemicals and dispose of waste responsibly.

| Method | Advantages | Considerations |

|---|---|---|

| Using Nitric Acid | Relatively simple method, does not require complex equipment | Requires proper handling of hazardous chemicals |

| Using Hydrochloric Acid and Hydrogen Peroxide | Does not produce harmful fumes | Requires patience due to longer processing time |

| Using Fire | Can be a quicker method | Requires careful handling of open flames |

Table: Comparison of Gold Extraction Methods

Conclusion

Gold recovery from computers through circuit board recycling is a practical method that individuals and companies can utilise to obtain valuable amounts of gold. By following the step-by-step guides mentioned, it is possible to extract gold from circuit boards and contribute to the recycling of electronic waste. Many large companies also employ similar procedures to lower the cost of gold mining and promote sustainable practices.

Electronic waste recycling plays a crucial role in precious metal extraction. Urban mining, as a form of sustainable resource management, helps conserve valuable minerals and metals while reducing the need for traditional mining extraction. This not only benefits the environment but also addresses the forecasted decline in mining resources.

However, it is important to take proper safety measures while handling chemicals involved in gold recovery from computers. Wearing protective equipment such as masks, goggles, and gloves is essential. Additionally, waste disposal should be done responsibly to minimise any potential environmental impact. Gold recovery from computers is not only financially rewarding but also beneficial for the environment and society as a whole.

FAQ

What is urban mining?

Urban mining is the process of recovering valuable minerals and metals, such as gold, from electronic devices or other recycled materials.

Why is gold recovery from circuit boards important?

Gold recovery from circuit boards is important because it helps conserve resources and reduce the need for mining extraction. It also provides a way to recycle electronic waste and recover valuable precious metals.

Can individuals perform gold recovery from circuit boards?

Yes, individuals can perform gold recovery from circuit boards with the right tools and chemicals. However, it is important to take proper safety precautions and follow step-by-step guides.

What tools are needed for gold recovery from circuit boards?

The tools needed for gold recovery from circuit boards include a glass container, metal bowl or tray, glass or metal rod for stirring, cloth filter, and steel tweezers. Protective equipment like a mask, goggles, and industrial gloves should also be worn.

What chemicals are used for gold recovery from circuit boards?

The chemicals used for gold recovery from circuit boards include concentrated nitric acid, hydrochloric acid, hydrogen peroxide, methanol, and gasoline. The specific chemicals used may vary depending on the chosen gold recovery method.

What methods can be used to extract gold from circuit boards?

There are several methods that can be used to extract gold from circuit boards, including manual removal, reverse electrolysis, and chemical solvent baths. Each method has its own advantages and requirements.

Is gold recovery from circuit boards financially rewarding?

Gold recovery from circuit boards can be financially rewarding, especially in larger quantities. However, it is important to note that the value of the recovered gold may fluctuate with market prices.

What are the benefits of gold recovery from computers?

Gold recovery from computers not only provides a source of valuable precious metals but also promotes the recycling of electronic waste and reduces the need for mining extraction. It is a sustainable practice that benefits the environment and society as a whole.