Salvaging the Future: Workstation Environmental Salvage

In today’s ever-changing world, creating a sustainable office environment has become a pressing need. One effective way to achieve this is through workstation environmental salvage. By salvaging materials from scrap, we can reduce waste, conserve resources, and ultimately reduce our carbon footprint.

The concept of workstation environmental salvage is simple yet impactful. Instead of discarding materials, we can salvage and repurpose them, giving them a new lease on life. This approach not only helps us reduce our waste output but also helps to minimize the environmental impact of the workstation industry.

By embracing workstation environmental salvage, businesses can play their part in building a sustainable future. Not only does it demonstrate a commitment to reducing their carbon footprint, but it also allows them to create a sustainable office space that aligns with their values. Additionally, implementing workstation environmental salvage practices can lead to long-term cost savings and improved brand reputation.

In this article, we will explore the environmental impact of salvaging materials, the benefits of workstation environmental salvage, and provide best practices for implementing this approach. Join us on this journey to salvage the future and create a sustainable office environment that reduces our carbon footprint.

The Environmental Impact of Salvaging Materials from Scrap

When salvaging materials from scrap, it is important to consider the environmental impact. The process of salvaging materials can consume significant amounts of energy, require large quantities of water, involve the use of chemicals and toxins, and generate waste. By understanding and minimizing these impacts, it is possible to implement workstation environmental salvage in a more sustainable manner.

One of the key environmental impacts of salvaging materials from scrap is energy consumption. The process of salvaging, including sorting, cleaning, and reconditioning, requires energy to power machinery and equipment. By using energy-efficient equipment and optimizing processes, the energy consumed during salvaging can be minimized.

Another significant environmental impact is water usage. Salvaging materials often involves washing and cleaning to remove dirt and contaminants. This can result in the utilization of large quantities of water. Employing water-saving techniques, such as recycling and reusing water, can help reduce water consumption during the salvaging process.

The use of chemicals and toxins is also a concern when salvaging materials. Certain materials may require the use of chemicals and solvents for cleaning or refurbishing purposes. However, it is crucial to handle these substances responsibly and ensure proper disposal to prevent pollution and minimize harm to the environment.

Additionally, the process of salvaging materials from scrap generates waste. This includes both non-recyclable waste and by-products produced during the salvaging process. Implementing effective waste management practices, such as recycling and proper disposal of non-recyclable waste, can help reduce the overall waste generated from salvaging.

By addressing these environmental impacts, companies and individuals can minimize the negative effects associated with salvaging materials from scrap and promote sustainable practices. Adopting energy-efficient technologies, implementing water-saving strategies, using environmentally friendly cleaning agents, and employing efficient waste management systems are key steps towards reducing the environmental footprint of workstation environmental salvage.

The Benefits of Salvaging Materials from Scrap

Salvaging materials from scrap offers a range of benefits for both individuals and businesses. By making use of discarded resources, you can unlock a variety of advantages that contribute to cost savings, environmental well-being, job creation, resource conservation, and an improved reputation.

Cost Savings

One of the primary benefits of salvaging materials from scrap is the potential for significant cost savings. Instead of purchasing new materials, salvaging allows you to repurpose existing resources, reducing the need for expensive investments. This approach not only lowers direct costs but also minimizes expenses related to transportation, storage, and waste management.

Environmental Benefits

By salvaging materials from scrap, you actively contribute to environmental sustainability. By reusing resources, you help reduce waste and the strain on landfills. Additionally, salvaging promotes resource conservation by reducing the need for new production. This reduction in resource consumption leads to lower energy usage and fewer greenhouse gas emissions, helping to mitigate the effects of climate change.

Job Creation

Implementing workstation environmental salvage initiatives can create job opportunities within the recycling and waste management industries. By salvaging materials from scrap, you support these sectors, enabling them to grow and hire more workers. This job creation has a positive impact on local communities, contributing to economic development and social well-being.

Resource Conservation

Salvaging materials from scrap is an effective strategy for conserving valuable resources. By repurposing existing materials, you help reduce the demand for new resources, such as timber, minerals, and water. This conservation approach supports sustainable practices by minimizing the extraction and depletion of natural resources, preserving them for future generations.

Improved Reputation

“Implementing workstation environmental salvage demonstrates a strong commitment to sustainability, which can enhance a company’s reputation.”

When businesses actively engage in salvaging materials from scrap, they showcase their dedication to environmental responsibility. This commitment can lead to an improved reputation among customers, investors, and stakeholders. By aligning with sustainable practices, companies can enhance their brand image, attract environmentally conscious customers, and gain a competitive advantage in the market.

Salvaging materials from scrap not only brings tangible benefits, such as cost savings and resource conservation, but also contributes to environmental stewardship and social well-being. By incorporating workstation environmental salvage into your business practices, you can create a more sustainable future while reaping the numerous advantages it offers.

Best Practices for Salvaging Materials from Scrap

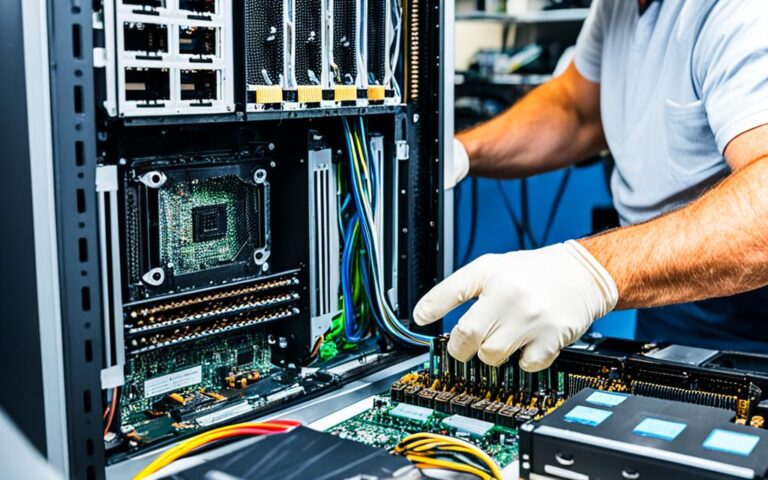

Implementing workstation environmental salvage requires following best practices to ensure safety and maximize the value obtained from salvaged materials.

- Prioritize Safety: Safety should always be the top concern when salvaging materials. Wear protective gear such as gloves, goggles, and masks to minimize the risk of injury.

- Sort and Separate: Proper sorting and separation of materials is essential for efficient salvage. Categorize items based on their material type to facilitate the salvaging process and prevent contamination.

- Choose the Right Tools: Using the right tools is crucial for effective salvaging. Select tools such as pry bars, wire cutters, and screwdrivers that are suitable for the materials you are working with.

- Maximize Value: To maximize value from salvaged materials, employ efficient and effective salvaging techniques. Carefully disassemble items, remove any reusable components, and store them properly for future use or sale.

By following these best practices, you can ensure a safe salvaging process while maximizing the value obtained from scrap materials.

Quote

Proper safety measures and smart sorting techniques are key to successfully salvaging materials from scrap and reducing waste. By choosing the right tools and maximizing the value of salvaged materials, we can contribute to a more sustainable future.

The Role of Collaboration and Innovation

Collaboration and innovation are crucial elements in driving the promotion and success of workstation environmental salvage. By collaborating with other stakeholders in the construction industry, businesses and individuals can harness collective knowledge and resources, enabling more effective workstation environmental salvage efforts. This collaborative approach facilitates the sharing of best practices, innovative ideas, and strategies for maximizing the positive impact of salvaging materials.

Innovation, on the other hand, plays a pivotal role in developing and implementing new technologies and approaches that further enhance the circular economy and promote sustainable construction practices. It is through continuous innovation that we can find creative solutions to the challenges posed by environmental salvage, streamlining processes, and reducing the overall environmental footprint of the workstation industry.

The Power of Collaboration

Collaboration fosters a sense of community among diverse stakeholders, including construction companies, suppliers, architects, and policymakers. When we come together, we can leverage each other’s expertise and experiences to create synergy. Through collaboration, businesses and individuals can identify opportunities for improvement, share cost-effective practices, and collectively address common challenges.

Collaboration is not just about reducing costs and sharing resources; it is about combining knowledge and expertise to create innovative solutions and spearhead change.

Innovation for a Sustainable Future

Innovation is the driving force behind the evolution of sustainable construction practices. By embracing technological advancements and novel ideas, the industry can continuously improve its environmental performance. This includes the development of cutting-edge recycling techniques, the adoption of renewable energy sources, and the exploration of alternative materials with reduced environmental impacts.

By pushing the boundaries of what is possible and thinking outside the box, we can unlock groundbreaking innovations that revolutionize the workstation industry and contribute to a more sustainable future.

Boosting the Circular Economy

Collaboration and innovation serve as catalysts for the circular economy, which aims to eliminate waste and regenerate resources. By salvaging materials from scrap, reusing and repurposing them, we can significantly reduce the demand for new resources and minimize environmental degradation. Collaboration allows us to optimize the use of salvaged materials and create a virtuous cycle of resource efficiency.

Innovation plays a critical role in developing technologies that enable circular practices, such as advanced sorting and processing systems. By embracing these innovative approaches, we can maximize the value extracted from salvaged materials, significantly contributing to the circular economy’s success.

Conclusion

In conclusion, the practice of workstation environmental salvage is essential for building a sustainable future. By salvaging materials from scrap, we can reduce waste, conserve resources, and minimize environmental impacts. This not only contributes to a circular economy but also promotes a greener and more sustainable work environment.

Workstation environmental salvage offers numerous benefits beyond cost savings. It provides environmental benefits by reducing waste and conserving resources, while also creating job opportunities in the recycling and waste management industries. Adhering to best practices and embracing collaboration and innovation allows us to maximize the value obtained from salvaged materials.

To achieve a sustainable future, it is crucial that businesses and individuals embrace workstation environmental salvage. By prioritizing this practice, we can mitigate our carbon footprints, contribute to a greener economy, and build a positive reputation as environmentally conscious. Let us take the necessary steps to pave the way towards a more sustainable and environmentally friendly future for all.

FAQ

What is workstation environmental salvage?

Workstation environmental salvage refers to the process of salvaging materials from scrap in order to create a sustainable office environment and reduce carbon footprints.

What is the environmental impact of salvaging materials from scrap?

When salvaging materials from scrap, it can consume significant amounts of energy, require large quantities of water, involve the use of chemicals and toxins, and generate waste.

What are the benefits of salvaging materials from scrap?

Salvaging materials from scrap brings benefits such as cost savings, environmental benefits, job creation, resource conservation, and improved reputation.

What are the best practices for salvaging materials from scrap?

Best practices for salvaging materials from scrap include prioritizing safety, sorting and separating materials, choosing the right tools, and maximizing the value of salvaged materials.

What is the role of collaboration and innovation in workstation environmental salvage?

Collaboration and innovation play crucial roles in promoting workstation environmental salvage by sharing best practices, resources, and knowledge, and developing new technologies and approaches.

Why is workstation environmental salvage important for creating a sustainable future?

Workstation environmental salvage is important as it helps reduce waste, conserve resources, minimize environmental impacts, and contribute to a circular economy.