Is PP (Polypropylene) Recyclable? A Guide to Recycling PP

Polypropylene (PP) is a highly versatile type of plastic used in many products, from packaging to car parts. Unfortunately, a large amount of PP is not recycled, which harms our environment. Understanding if PP can be recycled and how to do it effectively is crucial, especially now. Shockingly, less than 10% of all plastic waste is recycled. This highlights the urgent need for better recycling methods and for everyone to know how recycling helps our planet.

It’s key to understand the advantages of recycling PP. Recycling PP saves energy and resources, and cuts down on greenhouse gases from making new plastic. Finding ways to deal with plastic waste is more important than ever. The first step in solving this problem is learning about PP and how we can recycle it better.

Key Takeaways

- Less than 1% of polypropylene is recycled in the US, largely due to complex recycling processes.

- Recycling polypropylene can help reduce waste and conserve valuable natural resources.

- PP can be transformed into various products, enhancing sustainability.

- Awareness regarding proper disposal is crucial to minimise environmental pollution.

- Strengthening PP recycling protocols is essential in combating the plastic crisis.

Understanding Polypropylene

Polypropylene, often called PP, is a versatile thermoplastic. It is popular in many industries due to its properties. It is lightweight, strong, and has great chemical resistance. This makes it widely used in different fields. Every year, over 2.25 billion kilograms of polypropylene are produced globally. This shows its big role in the plastic market.

What is Polypropylene (PP)?

Polypropylene is a polymer made by combining propylene gas. It’s light and strong, with a recycling code number 5. Its properties make it resist acids, bases, and solvents well. It also withstands high temperatures. You can find polypropylene in things like:

- Packaging materials, especially for food

- Automotive parts, including bumpers and trims

- Medical supplies, like syringes and bottles

- Household items and textiles

Common Uses of Polypropylene

Polypropylene’s use is vast, showing its flexibility and strength. Different industries prefer it for various products:

| Industry | Percentage Usage | Examples of PP Products |

|---|---|---|

| Packaging | 30% | Yoghurt pots, takeout containers, food wrappers |

| Automotive | 10% | Bumpers, interior trim |

| Electrical Equipment | 13% | Insulation, connectors |

| Household Appliances | 10% | Storage containers, furniture |

| Medical | Not specified | Syringes, IV bags |

The wide use of PP highlights its key part in modern making and products. This makes finding good recycling methods crucial for our planet’s health. Some polypropylene items can be hard to dispose of correctly. Not all can be recycled easily. Knowing polypropylene characteristics is important for good use and recycling.

Is PP Recyclable?

Polypropylene (PP) is central to lots of everyday items. Yet, we often wonder if it can be recycled. The recycling symbol for PP sheds light on how it’s processed and the challenges recycling centres face.

The Recycling Code for Polypropylene

The recycling symbol for PP is a number 5 inside a triangle of arrows. This symbol helps identify the type of plastic. However, it doesn’t mean all recycling centres will accept it. Many places find PP hard to recycle. This is why only about 1% of PP gets recycled, raising big environmental worries.

Challenges in Recycling PP

Recycling PP comes with its fair share of hurdles. The biggest problem is the variety of PP items. Their different shapes, sizes, and colours make sorting hard. Also, items made from other materials can contaminate the PP, making things even harder.

Turning recycled PP into a high-quality product often fails. But, chemical recycling, like pyrolysis, offers some hope. Yet, not all communities have the right facilities for it. So, many PP items, including takeaway containers, just get thrown away. They pile up in landfills, increasing strain and possibly harming the environment.

Importance of Recycling Polypropylene

Recycling polypropylene is key for ecological health and saving money. Yet, only about 1% of it is recycled today. This means a big chance to do good and save resources is being missed. By recycling more, we can cut down the harm to the environment.

Environmental Benefits of PP Recycling

The benefits to the environment from recycling polypropylene are huge. Recycling a ton of plastic saves lots of energy, around 5,774 kilowatt-hours. This is like saving 16.3 barrels of oil, which helps conserve precious resources. Plus, it stops plastic from ending up in landfills, where it takes decades to break down.

Reducing Waste and Conserving Resources

Making recycling a common practice can lessen our use of fossil fuels, which are majorly used in making plastics. This not only reduces the need for new materials but also supports a sustainable economy. When companies recycle more, they cut costs and help the planet. Through chemical recycling, we can turn old plastics into new, high-quality materials. This improves how we use resources through recycling.

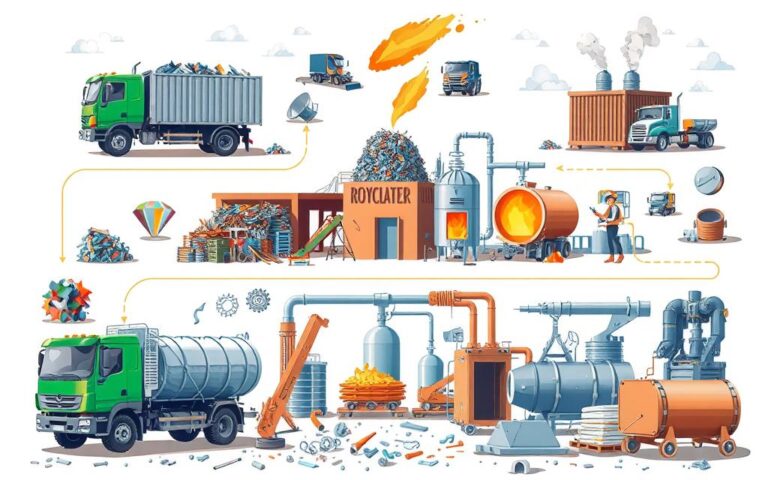

The Polypropylene Recycling Process

The polypropylene recycling process starts by gathering PP materials. This is vital and often needs help from professional waste carriers. Especially for companies with a lot of polypropylene. The next step is sorting. Here, polypropylene is carefully separated from other plastics and unwanted materials. This is crucial for a successful recycling process.

Collection and Sorting

The collection and sorting phases are key to high-quality recycled products. After collecting, the PP materials are cleaned well. This is to remove any contaminants. Such impurities can greatly lower the recycled polypropylene’s quality. So, getting rid of them is essential.

Shredding and Cleaning

After sorting, the polypropylene gets shredded into small pieces. This makes it easier to manage later on. Then, it undergoes further cleaning. This step is crucial to remove all leftover impurities. It prepares the PP for the next stages of recycling. These steps are crucial for making top-notch recycled material.

Compounding New Materials

The last step involves turning polypropylene into pellets. This happens in an extruder that melts the PP flakes. Then, these recycled pellets are used to make new products. This supports eco-friendly practices. Recycling polypropylene saves resources, cuts landfill use, and lowers energy usage. It completes the polypropylene recycling cycle.

FAQ

Is polypropylene (PP) recyclable?

Yes, polypropylene is technically recyclable. The problem is, many recycling programmes find it difficult to handle. This is due to issues like contamination and sorting.

What does the recycling symbol for polypropylene look like?

The recycling symbol for polypropylene is a triangle made of three arrows. Inside the triangle, you’ll see the number 5. This shows it’s classified under certain plastic systems.

What are the common uses of polypropylene?

Polypropylene is used in many things. You find it in food packaging, such as yoghurt pots and microwavable meals. It’s also in car parts, like bumpers and door trims.

And in household items. For example, storage containers and reusable bags are often made from it.

What are the environmental benefits of recycling polypropylene?

Recycling polypropylene has several benefits. It reduces waste and saves resources. It also lowers the emissions that warm our planet.

This means less need for new materials. And that helps lessen the harm from making more plastic.

What challenges are faced in recycling polypropylene?

Recycling polypropylene comes with challenges. The variety of shapes and colours of PP products complicates things. Non-PP materials mixed in cause contamination.

Also, many home recycling systems aren’t set up to deal with PP properly.

What does the recycling process for polypropylene involve?

First, PP materials are collected. Then, they go through sorting and cleaning to get rid of unwanted stuff. Next, they’re shredded into small pieces.

Finally, these pieces are made into pellets. These pellets can then be used to make new products.

How can I ensure that my polypropylene products are recycled?

To help your PP products get recycled, check your local rules. See if your area’s recycling programme accepts PP. Also, keep your items clean and without any non-PP materials.

What happens to polypropylene waste if it is not recycled?

Non-recycled polypropylene usually ends up in landfills. There, it can take a long time to break down. This not only releases dangerous emissions but also harms our soil and water.