Is MDF Recyclable? Disposal and Recycling Options

Medium-Density Fibreboard, or MDF, is popular in construction and furniture making. Yet, its environmental impact is now under the spotlight. The main issue is how we dispose of MDF. Much of it ends up in landfills, where it can release harmful formaldehyde.

In the last 20 years, there’s been hope for MDF recycling. Early 2000s research into using microwave technology for recycling MDF showed promise. Companies like MDF Recovery Ltd have been working on making recycling a reality since 2009. They aim to create sustainable and eco-friendly disposal options.

Looking into how we recycle MDF reveals the impact of its disposal. It points out how crucial it is to find sustainable ways to deal with MDF. This is important for building a circular economy that benefits everyone.

Understanding MDF and Its Composition

MDF stands for Medium Density Fibreboard, a known engineered wood product. It’s famous for its strength and flexibility. The main ingredients are wood fibres from timber and a resin binder, often urea-formaldehyde. These create a smooth and uniform material, making it perfect for construction and furniture.

What is MDF?

MDF is made by compressing fine wood fibres at high temperatures, up to 240 degrees Celsius. This produces dense boards used in many ways, like in cabinets and decorative pieces. Its durability makes it excellent for home and business interiors.

How MDF is Manufactured

The creation of MDF involves turning wood waste into fibres. These are mixed with resin and wax. Then, they’re heated and pressed into solid panels. The result is a durable material. You can find MDF in various grades, each designed for different environments.

The Role of Resin and Formaldehyde

Resin is key to MDF’s strength and stability. However, urea-formaldehyde resins can release harmful formaldehyde. This has led to a push for safer alternatives, like Carb P2 MDF. This type meets strict international rules for lower emissions. Knowing about these options can help buyers choose safer wood products.

The Challenges of Recycling MDF

Recycling MDF faces big hurdles that hinder waste management efforts. It’s vital to grasp these challenges to tackle the environmental issues caused by MDF disposal. The difficulty comes from its special make-up and how it’s made.

Why is MDF Difficult to Recycle?

The tough part about recycling MDF is its resin, often based on formaldehyde. This not only prevents MDF from breaking down but also makes recycling harder. When MDF is treated with glues and coatings, it can let out dangerous substances, which makes recycling centres wary.

Common Recycling Obstacles

Several obstacles make recycling MDF harder:

- Contamination: MDF might have unwanted stuff like metal or paint, making it hard to separate during processing.

- Property Deterioration: Recycling MDF can lower the quality of the wood fibres, which affects how the recycled product can be used.

- Market Demand: The push for turning wood into energy has caused a lack of raw materials for making MDF, affecting recycling availability.

| Recycling Challenge | Impact on Recycling Efforts |

|---|---|

| Contamination with Metal/Paint | Makes processing more expensive and less efficient |

| Low Quality of Recycled Fibres | Restricts uses and reduces the value of recycled boards |

| Competition for Raw Materials | Leads to less material for recycling due to more energy production |

These challenges highlight the importance of finding new ways to deal with MDF waste. This can help reduce its negative impact on the environment.

Is MDF Recyclable?

The topic of whether Medium-density fibreboard (MDF) is recyclable is gaining attention. This is due to rising sustainability concerns. Various options for recycling MDF are being explored. These efforts show hope for a greener future for this commonly used material.

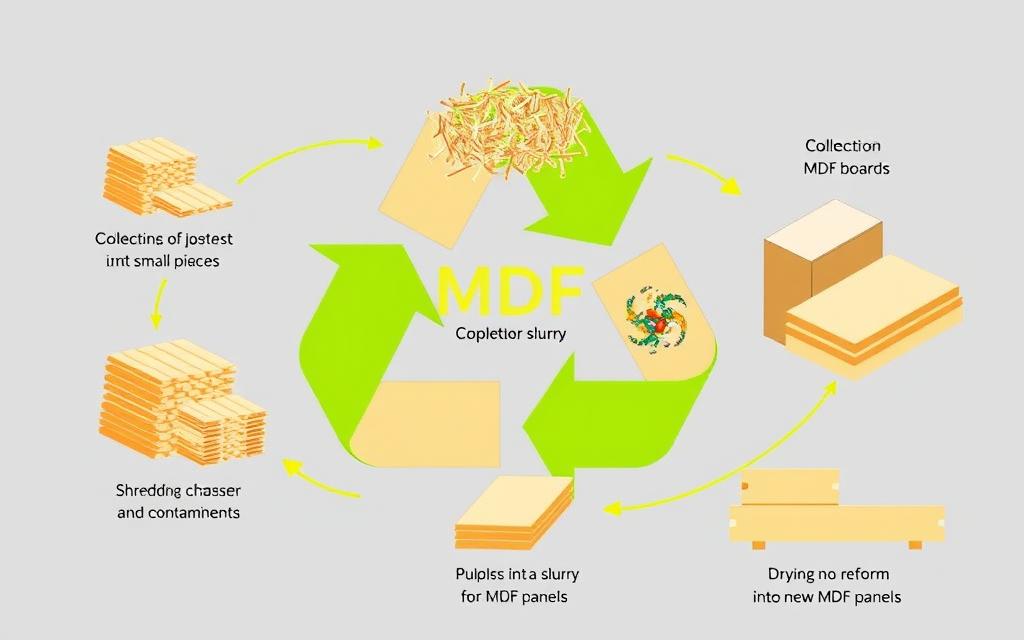

Current Recycling Options Available

Unilin Panels is leading the way in making MDF sustainable. They aim to use 25% recycled fibres in their MDF wood mix by 2030. This will help store 380,000 tonnes of CO2 a year. Their efforts are a big step towards using more recycled materials in making MDF. They have developed technology that lets wood fibres be reused. This innovation doubles the life of high-quality MDF panels.

Innovative Techniques for MDF Recycling

MDF Recovery Ltd is introducing new ways to recycle MDF. Their process has been proven by the BioComposites Centre. It shows that recycling can be effective without losing fibre quality. They are constantly testing new methods to recover valuable materials from MDF waste. This shows a move towards more eco-friendly practices in the industry.

Sustainable Disposal Methods for MDF

It’s crucial to manage MDF waste well to keep the planet green. Many methods exist that focus on eco-friendly disposal. These help lower the harm to our environment and follow good waste management rules. People and companies have various ways to deal with MDF waste rather than just throwing it away.

Responsible Disposal Options

Choosing greener ways to dispose of MDF can cut down on landfill waste. Here are some good choices:

- Recycling: A lot of MDF can be recycled. 65% turns into biomass fuel, 26% gets used again in panel boards, and 9% goes to animal bedding and landscaping.

- Donation: If MDF items are still in good shape, they can be given to charities or community projects. This approach supports reuse and helps meet local needs.

- Repurposing: Getting creative with unwanted MDF, like making furniture or decor, is a great way to be eco-friendly. It also gives the MDF a new purpose.

Limitations of Landfill Disposal

Using landfills for MDF waste has big downsides, mostly for the environment. Here’s why:

- Toxic leaching: MDF can carry harmful substances like formaldehyde that might leak into the ground and water, posing a contamination threat.

- Increased regulations: New rules about wood waste point out ten types of hazardous wood that need careful disposal to prevent harming nature.

- Cost implications: Getting rid of MDF this way could get pricier due to limited landfill space and tougher rules requiring detailed sorting of hazardous waste.

Using sustainable disposal methods is key for ethical waste management. This ensures we can avoid dumping MDF in landfills. Moving towards responsible waste practices matches what people want: more eco-friendly options and better results for our environment.

| Disposal Method | Benefits | Challenges |

|---|---|---|

| Recycling | Reduces landfill waste; provides raw materials for new products | Requires sorting and collection logistics |

| Donation | Promotes community support; extends product life | Finding appropriate recipients |

| Repurposing | Encourages creativity; minimises waste | Skill and time investment needed |

| Landfill Disposal | Simple and readily available | Environmental risks; cost increases |

Alternative Materials to MDF

More and more people want to use products that are kind to the environment. They are choosing materials like Chip[s] Board, made from waste potato peelings. This creative solution reduces waste. It also offers an alternative to MDF, which is often hard to recycle. Chip[s] Board is better for the planet because it’s more biodegradable and less toxic.

Comparative Analysis with Other Wood Products

Beside Chip[s] Board, other materials like plywood and recycled particleboard are great alternatives. Plywood is strong and versatile, perfect for furniture and cabinets. Innovations such as rice MDF, produced by CalPlant, are making waves too. They aim to cut down on formaldehyde emissions. Plus, they make good use of waste materials, addressing key environmental issues tied to traditional MDF production.

Benefits of Using Eco-Friendly Options

Choosing sustainable materials is good for both our health and the planet. By picking eco-friendly options, we help cut down on harmful emissions and waste. This move towards greener alternatives tackles food waste and factory pollution. It also encourages us to make thoughtful choices, leading to a healthier earth.

FAQ

What is MDF?

MDF stands for Medium-Density Fibreboard. It’s made by mixing wood fibres with resin and wax. This mix makes MDF a go-to material for different uses.

How is MDF Manufactured?

To make MDF, wood fibres and resin are pressed together at high temperatures. This process creates a dense, smooth sheet. It’s widely used in making furniture and in construction.

What are the Risks Associated with Formaldehyde in MDF?

MDF has resin that can contain formaldehyde, posing health risks. Like asbestos, it can release harmful fumes over time, raising health concerns.

Why is MDF Difficult to Recycle?

Recycling MDF is hard because it’s not biodegradable due to its resin. This complicates its processing and impacts the environment during disposal.

What Common Obstacles are Faced in Recycling MDF?

Recycling MDF can be tricky. It’s often contaminated with metal and paint, making recycling harder and complicating waste management.

Are There Current Recycling Options Available for MDF?

Nowadays, companies like MDF Recovery Ltd are breaking new ground. They use innovative tech to recycle MDF efficiently, turning waste into high-quality wood fibre.

What Innovative Techniques are Used for MDF Recycling?

New methods like ohmic heating and continuous processing are changing MDF recycling. They enable better and more sustainable waste management practices.

What are Responsible Disposal Options for MDF?

For MDF disposal, consider re-using or donating. Repurposing is also better than just throwing it away. It’s about finding alternatives to landfill.

What are the Limitations of Landfill Disposal?

Using landfills for MDF disposal poses dangers. Toxic formaldehyde can leak into our environment. We need to think about greener disposal methods.

How Does MDF Compare to Other Wood Products?

MDF is often weighed against other woods. Alternatives like plywood or recycled particleboard, and solid wood are greener choices.

What are the Benefits of Using Eco-Friendly Options?

Eco-friendly materials come with less toxicity and better biodegradability. They also offer health benefits, meeting the demand for sustainable building and furniture materials.