How Is Metal Recycled? An Overview of the Process

The metal recycling process plays a big role in keeping our planet green. By recycling, we save natural resources and use less energy than mining new stuff does. Sadly, only 30% of metal is recycled now, but there’s room to do better. Things like cans, car parts, and old appliances start this journey. They go to recycling centres to become new materials.

Recycling metal helps the Earth and can make some money too. People and companies get paid for their old metal. And making things from recycled metal costs less than using new resources. This practice creates jobs and helps our economy grow. When we focus on “Reduce, Reuse, Recycle,” we manage waste better. This stops harmful chemicals from ruining our soil and water.

Your Role in Metal Recycling

Getting involved in metal recycling starts with understanding metal waste. Both individuals and businesses play a key role. They ensure recyclable materials are correctly identified and sent to recycling centres. Scrap metal is any material that’s mainly metal, covering ferrous and non-ferrous types. Iron and steel are ferrous metals, while non-ferrous metals include valuable ones like aluminium and copper.

Understanding Metal Waste

Knowing what items are scrap metal can boost recycling. Common scrap items in homes include pots, pans, parts of bicycles, grills, and garden furniture. For example, in Vermont, big appliances like fridges and cookers are seen as scrap metal. They must not go into landfills. Facilities must take apart any appliance with dangerous substances, like refrigerants, safely.

Preparing Scrap Metal for Collection

To get ready for metal recycling, sort the scrap by type and cleanliness. Proper preparation raises the worth of materials at recycling places. Tools like magnets help tell ferrous from non-ferrous metals. Companies might do a scrap audit to get better at managing metal waste and increase profits. While small amounts might be recycled for free, larger batches could cost a little. Always keep small metal parts away from kids to prevent accidents.

Recycling metal helps save energy, lessen emissions, and boosts the economy. Steel is one of the top recycled materials worldwide. This effort supports sustainable future practices.

Explore more facts about metal recycling.

Collection

Efficient collection of scrap metal uses many methods. These depend on how much and what kind we gather. The first step is picking the best strategy for places like building sites or factories. Making the collection process better helps a lot with recycling.

Methods of Collection

There are different ways to collect scrap metal that help with productivity and ease. Some common methods are:

- Dedicated recycling bins: Using special bins for different metals helps keep things organised.

- Scheduled pickups: For big jobs, having a set schedule for collections keeps scrap under control.

- Drop-off centres: People can easily take their scrap metal to local spots.

Businesses might also work with experts to sort and move metals in a smart way. This makes the process better for everyone. It’s important to keep scrap metal in good condition from start to finish.

Importance of Proper Containers

Using the right recycling bins is key for good scrap metal collection. These bins are made to stop contamination and keep the metal quality high. The main benefits of the correct bins are:

- Enhanced safety: They lower the chance of accidents while handling.

- Improved material integrity: They ensure metals stay clean until it’s time to process them.

- Facilitated transportation: They make moving scrap to recycle spots easier.

Working together with recycling companies for big hauls makes things simpler. Starting these practices helps our recycling system stay healthy.

Sorting

The metal sorting process is key in recycling, making sure we keep valuable metals. Recycling centres first separate metals from non-recyclables. This is essential for a smooth recycling operation.

Classifying Metal Types

Metals are sorted into two main groups: ferrous and non-ferrous. Ferrous metals have iron and are magnetic. They include steel and cast iron. For example:

- Steel – found in cars, beams, and appliances.

- Cast Iron – used in pipes, engine parts, and pans.

Non-ferrous metals don’t stick to magnets. They’re valuable for being rust-resistant and good conductors. Some well-known examples include:

- Aluminium – in cans and car parts.

- Copper – mainly in wires and pipes.

- Brass – in taps and musical gear.

- Stainless Steel – in kitchens and hospitals.

Clean metals fetch a higher price at recycling centres. If metals are dirty, like rusty or oxidised, they’re harder to recycle. Working with trusted recycling centres can make scrap metal more profitable. This is because metal prices often change.

Quality Assurance in Sorting

Advanced tech, like PXRF devices and infra-red scans, helps sort metals quickly. It ensures metals are of high value and quality. Training and sticking to standards are important. Bodies like PAS help with this.

Knowing the differences between ferrous and non-ferrous metals helps in sorting them right. As recycling advances, new tech helps make it better and greener. For more info on metal recycling, visit this resource.

Processing

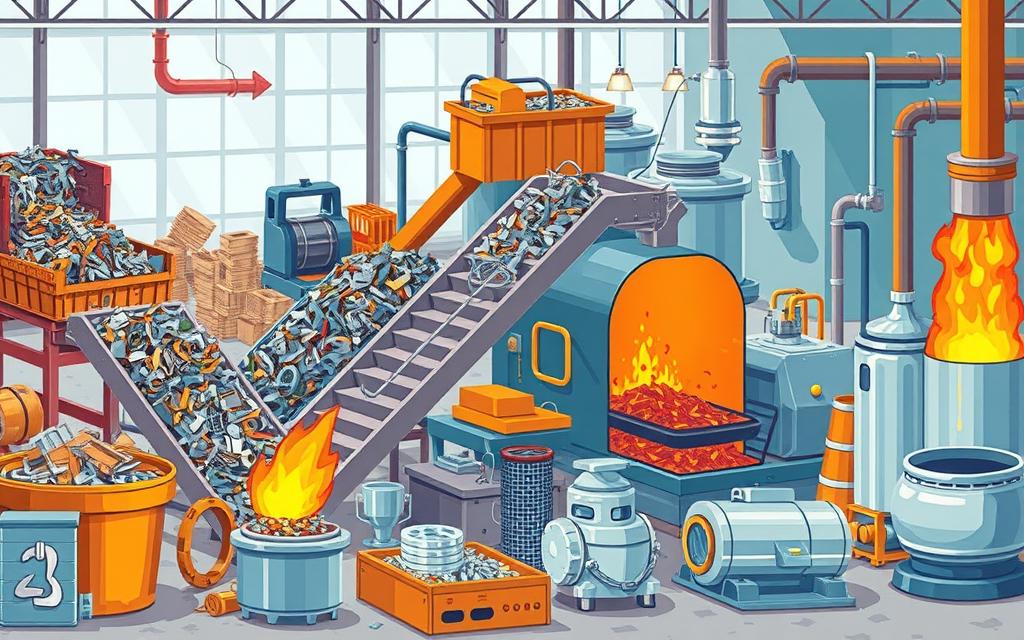

The processing of scrap metal boosts recycling efforts hugely. Different techniques prepare metals for reuse. Two key methods are squashing the metal and shredding it. These steps improve the recycling process.

Compaction Techniques

Metal squashing is a vital initial step. It uses strong machinery to press the metal, making it much smaller. This saves space, making transport and storage cheaper and easier. It’s very useful for handling big items like cars or large appliances.

Shredding and Size Reduction

After squashing, metals are then shredded into tinier pieces. Hammer mills are commonly used here. Shredding increases the metal’s surface, helping in later stages like melting. Smaller metal pieces melt more efficiently and produce better final products. These steps underline the importance of good metal processing in recycling.

How Is Metal Recycled?

The cycle of metal recycling transforms used metals into precious resources. It starts by gathering metal products from homes and industries. After collection, the metals are sorted with care. This ensures each type is properly identified, which is key for the quality of the recycled outcome.

Overview of the Recycling Circle

In this overview, sorted metals are processed. This usually means shredding and melting them. These steps cut down the material volume and get them ready for making new products. Metals like aluminium and steel are central to recycling globally. They can be recycled over and over without losing quality, making them vital for uses ranging from building to making consumer goods.

Recycling metals greatly reduces environmental harm. It lessens the need to mine fresh materials, saves natural resources, and cuts down on harmful gases. Thanks to better technology like advanced sorting sensors, we can now recycle more metals than before. This improves the recycling process. Companies such as C.D.Dodd have shown for more than 20 years how good recycling can support our economy and help our planet. This highlights why it’s crucial we keep recycling metals.

FAQ

What is the metal recycling process?

Collecting scrap metal products starts the metal recycling process. Then, they are sorted at recycling centres and prepared for remaking new items. This helps save natural resources and use less energy. It follows the “Reduce, Reuse, Recycle” idea.

How can I identify scrap metal?

You can spot scrap metal as either ferrous (with iron) or non-ferrous metals (like aluminium and copper). Sorting them right is key to recycle effectively and get the most out of them.

What is the importance of preparing scrap metal properly?

Getting scrap metal ready means sorting it by its type and cleanliness. This step is crucial for boosting its value when it’s recycled. Magnets can help tell apart ferrous from non-ferrous metals.

What methods are used for collecting scrap metal?

To collect scrap metal, you can use special bins for different metals. Use the right containers to keep the metals in good condition. Some recycle companies might also help by picking up big loads.

Why is the sorting process necessary in recycling?

Sorting is important because it keeps metals away from non-recyclable stuff. It also sorts metals into ferrous and non-ferrous groups. Magnets help with this, making sure recycling works well.

What techniques are involved in processing scrap metal?

Processing scrap metal involves squashing it to save space. Then, it’s shredded in hammer mills. These steps make the metal easier to melt. They help recycle metal more efficiently.

What does the recycling circle entail?

The recycling circle is the journey of metals from being used to making new items. It covers collection, sorting, processing, melting, and delivery to manufacturers. This cycle cuts down energy use a lot compared to getting new metals.